HAZMAT Ops courses, lasting five days, equip responders with vital knowledge and skills. Over a million daily shipments necessitate comprehensive training and adherence to regulations.

Hazardous materials are surprisingly commonplace, with over one million shipments traversing U.S. commerce daily. This widespread presence underscores the critical need for comprehensive understanding and safe handling practices. A frequent misconception is that these materials are exclusively industrial or highly specialized; however, they encompass a broad spectrum of substances encountered in everyday life, from cleaning supplies to fuels.

Effective hazardous materials operations require recognizing that these substances pose potential risks to health, safety, property, and the environment. The nature of these risks varies significantly depending on the material’s properties – flammability, toxicity, reactivity, and corrosivity are key considerations. Understanding these characteristics is fundamental to implementing appropriate safety measures;

Furthermore, awareness of the regulatory landscape governing hazardous materials is paramount. Compliance with standards set by organizations like OSHA, PHMSA, and adherence to guidelines like the Emergency Response Guidebook (ERG) are essential for responsible operations. This introductory overview sets the stage for a deeper dive into specific regulations, hazard classes, and emergency response protocols.

Understanding Hazardous Materials Regulations

Compliance with hazardous materials regulations is not merely a legal obligation, but a cornerstone of safe operations and environmental protection. Organizations handling these substances must navigate a complex web of rules, primarily driven by OSHA’s Hazardous Waste Operations and Emergency Response (HAZWOPER) standards. These regulations mandate comprehensive employee training, record-keeping, and certification to ensure competency.

Beyond OSHA, the Pipeline and Hazardous Materials Safety Administration (PHMSA) plays a crucial role, particularly concerning transportation. PHMSA addresses questions regarding hazardous materials through Interpretive Response Letters (IRL), clarifying requirements and ensuring consistent application of the rules. Understanding these interpretations is vital for avoiding compliance issues.

Employers are responsible for ensuring their hazmat employees receive, and can demonstrate, adequate training. This includes initial certification and ongoing refresher courses. Maintaining detailed training records is essential for demonstrating compliance during inspections. Regulations also extend to specific locations, as outlined in the National Electrical Code (NEC) Chapter 5, defining “classified” areas requiring specialized safety measures.

OSHA HAZWOPER and Hazardous Materials Operations

The Occupational Safety and Health Administration’s (OSHA) Hazardous Waste Operations and Emergency Response (HAZWOPER) regulation (29 CFR 1910.120) is central to hazardous materials operations. It establishes requirements for workers involved in cleaning up hazardous waste sites, responding to emergencies involving releases, and handling hazardous materials. A key component is tiered training, progressing from awareness to technician levels.

Hazardous materials technicians, as per 29 CFR 1910.120(q)(6), require 24 hours of first responder operations-level training, alongside demonstrated competency in critical skills. This foundational training is often an 8-hour course, expanding to 24 hours when incorporating Self-Contained Breathing Apparatus (SCBA) and decontamination procedures.

HAZWOPER emphasizes the importance of site safety and control, requiring detailed plans and procedures to mitigate risks. Employers must provide appropriate Personal Protective Equipment (PPE) and ensure employees are proficient in its use. Regular drills and exercises are crucial for maintaining readiness and reinforcing safe work practices. Continuous training and record-keeping are non-negotiable aspects of HAZWOPER compliance.

PHMSA Regulations and Compliance

The Pipeline and Hazardous Materials Safety Administration (PHMSA) plays a critical role in regulating the safe transportation of hazardous materials within the United States. PHMSA’s regulations govern everything from classification and packaging to labeling, placarding, and shipping documentation. These rules aim to prevent incidents and protect the public and the environment.

PHMSA frequently issues Interpretive Response Letters (IRLs) to clarify ambiguities and provide guidance on specific regulatory questions. Staying current with these IRLs is vital for ensuring compliance. Employers are responsible for properly classifying hazardous materials, selecting appropriate packaging, and accurately completing shipping papers.

Compliance with PHMSA regulations extends to all modes of transportation – highway, rail, air, and water. Each hazmat employer must train and test their hazmat employees, certify their training, and maintain detailed records. Failure to comply can result in significant fines and penalties. Understanding these regulations is paramount for safe and legal hazardous materials operations.

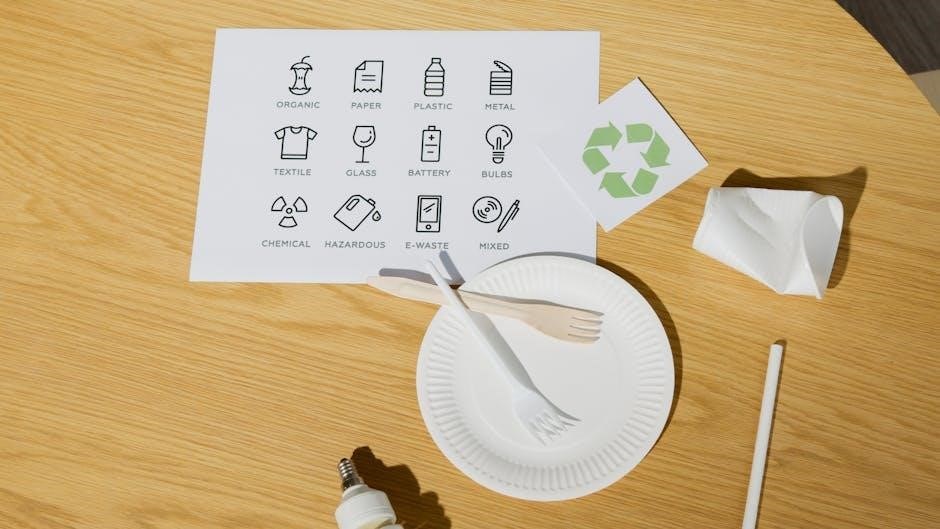

Hazardous Materials Identification

Accurate identification of hazardous materials is the cornerstone of safe handling and emergency response. It begins with recognizing that hazardous materials are surprisingly commonplace, traveling via various transportation methods daily – exceeding one million shipments in U.S. commerce. This necessitates a robust understanding of identification methods.

Key identification tools include shipping papers, product labels, and placards. Shipping papers provide detailed information about the material, including its proper shipping name, hazard class, and UN identification number. Labels and placards offer a quick visual indication of the hazards present.

However, relying solely on these may not always be sufficient. Responders must also be familiar with the Emergency Response Guidebook (ERG), a crucial resource for initial hazard assessment. Proper identification informs the selection of appropriate personal protective equipment (PPE) and dictates the necessary response procedures, minimizing risks during hazardous materials operations.

Hazard Classes and Divisions

Hazardous materials are systematically categorized into nine hazard classes, each representing a distinct type of risk. These classes are further divided into divisions to provide more specific hazard information. Understanding these classifications is fundamental for safe handling and effective emergency response during hazardous materials operations.

Class 1 encompasses explosives, while Class 2 covers gases – including compressed, liquefied, and dissolved gases. Class 3 deals with flammable liquids, and Class 4 focuses on flammable solids, substances that are spontaneously combustible, or those that react when exposed to water.

Classes 5 and 6 cover oxidizers and toxic substances, respectively. Class 7 is dedicated to radioactive materials. Classes 8 and 9 include corrosive substances and miscellaneous hazardous materials, respectively. Proper identification of the hazard class dictates the appropriate response protocols and PPE requirements, ensuring responder safety and environmental protection.

Shipping Papers and Documentation

Accurate and complete shipping papers are crucial for identifying hazardous materials during transport and emergency response. These documents provide essential information about the substance, including its proper shipping name, hazard class, UN identification number, and quantity. Hazmat employees are legally obligated to ensure shipping papers are readily available and accompany the shipment.

Shipping papers must conform to specific regulatory requirements, detailing the material’s hazards and necessary precautions. They serve as a primary source of information for first responders, enabling them to assess the situation and implement appropriate safety measures. Understanding the layout and content of these documents is a core competency for personnel involved in hazardous materials operations.

Furthermore, documentation extends beyond the basic shipping paper to include emergency response information, such as contact details and procedures for handling spills or leaks. Maintaining meticulous records is vital for compliance and accountability.

Emergency Response Guidebook (ERG)

The Emergency Response Guidebook (ERG) is a vital resource for first responders and hazmat personnel dealing with incidents involving hazardous materials. Published by PHMSA, the ERG provides a quick and readily accessible guide to initial response actions. It’s designed to be used as a preliminary source of information until more detailed guidance can be obtained.

The ERG organizes information by four-digit UN identification number, allowing responders to quickly locate relevant guidance based on the material involved. Each entry includes hazard information, protective actions, and emergency contact details. Color-coded pages further enhance rapid identification of hazard levels – from light blue for minimal hazard to severe red for high danger.

Understanding how to effectively utilize the ERG is a fundamental skill in hazardous materials operations. Regular updates ensure the ERG reflects current regulations and best practices, making it an indispensable tool for safe and effective incident management.

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) is crucial for safeguarding responders during hazardous materials incidents. The selection of appropriate PPE depends heavily on the specific hazards present, including the chemical’s properties, concentration, and potential routes of exposure. A thorough hazard assessment is the first step in determining the necessary level of protection.

Essential PPE often includes respiratory protection, such as Self-Contained Breathing Apparatus (SCBA) or air-purifying respirators, alongside protective clothing like chemical-resistant suits, gloves, and boots. Eye and face protection, including goggles and face shields, are also vital to prevent contact with splashes or vapors.

Proper training on the correct donning, doffing, and limitations of PPE is paramount. Decontamination procedures for PPE are equally important to prevent secondary exposure. Remember, PPE is a barrier, not an absolute shield, and must be used in conjunction with other safety measures.

Levels of Hazardous Materials Training

Hazardous Materials (Hazmat) training is structured into distinct levels, each building upon the previous one to ensure responders possess the necessary competencies. These levels, defined by standards like OSHA’s HAZWOPER, cater to varying roles and responsibilities in a hazmat incident.

The foundational level is Awareness, providing a basic understanding of hazards. Operations-level training, typically 8-24 hours, focuses on defensive strategies and site control. Technicians receive more in-depth training – including 24 hours of first responder operations level training – enabling them to actively mitigate incidents.

Specialists are experts in chemical properties and hazard control, while Incident Commanders manage the overall response. Employers are legally obligated to provide and document current training for all hazmat employees, ensuring compliance with regulations. Age requirements for certain certifications, like Operations, often start at 16 years old.

Operations Level Training Requirements

Operations-level training is crucial for personnel who respond to releases of hazardous materials, taking a defensive approach. This training, generally 8 hours long – potentially extending to 24 hours with SCBA and decontamination components – focuses on protecting oneself and the public, not actively stopping the release.

Key requirements include understanding hazard communication systems like the Emergency Response Guidebook (ERG), selecting appropriate Personal Protective Equipment (PPE), and implementing basic site control measures. Trainees learn to identify hazardous materials, assess risks, and initiate notifications.

Competency in decontamination procedures is often included, especially with extended training durations. Successful completion necessitates both training and testing, with employers responsible for certification and record-keeping. This level prepares responders to function effectively within an Incident Command System, supporting more specialized teams.

First Responder Operations Level Training

First Responder Operations Level training, a foundational step in hazardous materials response, builds upon awareness-level knowledge. It’s designed for individuals likely to witness or discover a hazardous materials incident, requiring an initial defensive response. This training, often a prerequisite for higher levels, emphasizes personal safety and scene stabilization.

The curriculum includes hazard recognition, isolation techniques, and notification procedures. Trainees learn to utilize the Emergency Response Guidebook (ERG) to quickly identify hazards and recommended actions. Understanding basic chemical properties and potential hazards is paramount.

Furthermore, 24 hours of this training is a requirement for Hazardous Materials Technicians, ensuring a solid base of operational knowledge. Successful completion involves both theoretical instruction and practical exercises, preparing responders to protect themselves and the public until more specialized personnel arrive. Certification and record retention are employer responsibilities;

Decontamination Procedures

Decontamination is a critical component of hazardous materials operations, aiming to remove or neutralize contaminants from people, equipment, and the environment. Procedures vary based on the hazard’s nature and extent of contamination, ranging from simple gross decontamination – removing visible contamination – to more complex chemical neutralization.

Effective decontamination requires establishing designated zones: a hot zone (contamination area), a warm zone (transition area), and a cold zone (support area). Personnel entering or exiting the hot zone must undergo decontamination to prevent secondary contamination.

Basic Operations level training often includes decontamination procedures, potentially extending the course length up to 24 hours if SCBAs and decontamination are necessary. Proper selection of decontamination solutions is vital, considering the specific hazard. Thorough rinsing and disposal of contaminated materials are essential to prevent further spread; Documentation of the entire process is also crucial for legal and safety reasons.

Site Safety and Control

Establishing robust site safety and control measures is paramount during hazardous materials incidents. This begins with a thorough site assessment to identify hazards, potential ignition sources, and access/egress routes. Implementing a clear perimeter and access control system prevents unauthorized entry and minimizes exposure risks.

The Incident Command System (ICS) provides a standardized framework for managing operations, ensuring clear communication and coordination among responders. Establishing zones – hot, warm, and cold – is crucial for controlling contamination and personnel movement. Continuous monitoring of the atmosphere for hazardous substances is essential, utilizing appropriate detection equipment.

Safety officers play a vital role in enforcing safety protocols, conducting regular briefings, and addressing potential hazards. Proper personal protective equipment (PPE) selection and use are non-negotiable. Detailed documentation of all safety measures and observations is critical for post-incident analysis and improvement. Compliance with OSHA regulations, particularly HAZWOPER, is mandatory for organizations handling hazardous materials.

Hazardous Materials Technician Requirements

Becoming a Hazardous Materials Technician demands a significant commitment to specialized training and competency. 29 CFR 1910.120(q)(6) stipulates that technicians must complete 24 hours of first responder operations level training as a foundational prerequisite. Beyond this, technicians require in-depth instruction covering chemical characteristics, hazard assessment, and advanced control strategies.

Technician-level training focuses on sophisticated plugging, patching, and containment techniques, alongside the proper use of specialized equipment. A thorough understanding of decontamination procedures, including personnel and equipment decon, is essential. Competency in selecting and utilizing appropriate personal protective equipment (PPE) for various hazard scenarios is also critical.

Successful completion of a recognized technician-level course, coupled with practical drills and exercises, is necessary. Maintaining current certifications and participating in refresher training ensures continued proficiency. Employers must verify technician qualifications and maintain detailed training records to demonstrate compliance with regulatory standards;

Age and Certification Requirements

Specific age requirements for hazardous materials training vary, but a minimum age of 16 years is generally mandated for initial certification, as evidenced by application stipulations. However, this is often coupled with additional requirements, such as parental or guardian consent for applicants under 18. Demonstrating a commitment to safety and responsibility is paramount.

Certification for Hazardous Materials Operations requires documented proof of completed training, aligning with OSHA regulations and HAZWOPER standards. Employers are legally obligated to train and test their hazmat employees, meticulously certifying the training provided. Maintaining comprehensive records of current training is crucial for compliance and audit purposes.

Certification isn’t a one-time event; refresher training is essential to maintain competency and stay abreast of evolving regulations. Organizations handling hazardous materials must prioritize ongoing training to ensure their personnel are adequately prepared to respond to incidents safely and effectively. Proof of completed Hazardous Materials Operations Training or Certification is a fundamental requirement.

Resources for Further Study

For in-depth knowledge of hazardous materials, the National Fire Protection Association (NFPA) offers a wealth of standards and guides. OSHA’s website provides comprehensive information on HAZWOPER regulations (29 CFR 1910.120), including detailed training requirements and compliance assistance materials. Regularly checking for updates is vital, as regulations evolve.

The Pipeline and Hazardous Materials Safety Administration (PHMSA) is an invaluable resource, offering interpretive letters and guidance on hazardous materials transportation regulations. OSU Fire Service Training provides advanced courses, like those offered at Kiamichi Tech, enhancing skills in hazardous materials response. These courses often cover practical scenarios and hands-on exercises.

The Emergency Response Guidebook (ERG), updated biennially, is a critical field reference for first responders. Online platforms and professional organizations dedicated to safety and environmental protection also offer valuable training materials and resources. Staying current with industry best practices and continuous professional development are key to maintaining expertise in hazardous materials operations.